DBT-ICT Centre for Energy Biosciences

The DBT-ICT Centre for Energy Biosciences (DBT-ICT-CEB) is a unique place with integrated basic and translational science capabilities for bioprocess development and scale up. Funded by The Department of Biotechnology, Ministry of Science and Technology, India, the Centre was established and formally inaugurated in May 2009. Built at a total cumulative cost equivalent to USD 10 Million, the Centre is a part of the Institute of Chemical Technology (ICT) at Matunga, Mumbai, which is a deemed University under Section 3 of UGC Act 1956. The Centre was set up as a result of vision and efforts of Dr. M. K. Bhan, Secretary DBT and Dr. Renu Swarup, Advisor DBT, and functions under the leadership of Dr. G. D. Yadav, Vice Chancellor, ICT. The projects and technical programs at the Centre are coordinated by Dr. Arvind Lali. The Centre is focused primarily at developing biotechnologies for deriving biofuels from renewable resources for reducing India’s rising dependence on petroleum fuels and cut down greenhouse gas emissions.

The motto of the Centre, as put by Dr. M. K. Bhan, Secretary, DBT, is “not doing new things, but doing the things in a new way” and indeed the Centre believes in building capacity at an Institute for development of integrated technology package. The Centre, besides being involved in technology development for many Indian and foreign companies, also actively collaborates with a number of industrial and academic partners. These collaborations are in the specific areas of Professor Arvind M. Lali B. Chem., M. Chem., Ph.D Tech. (Chemical Engineering), Professor (Chemical Engineering) Head, DBT-ICT Centre for Energy Biosciences “The Centre is focused on providing cutting edge technologies to the country in the areas of Bioenergy and Industrial Biotechnology” DBT-ICT Centre for Energy Biosciences I Institute of Chemical Technology I 7 separation sciences, analytical sciences, biomass-to-liquid fuel technologies, biorefinery development, plant biotechnology, enzyme technology, and metabolic engineering. Besides these, several other collaborations are under formation. The breadth and integration of various disciplines at the Centre, and its collaborators makes it an outstanding place which aims at developing cutting edge technologies in a global research scenario. At any given time the Centre has more than 50 Ph.D scholars in various disciplines like chemical engineering, chemistry, bioprocess technology, biotechnology, biochemistry, microbiology, and molecular & synthetic biology.

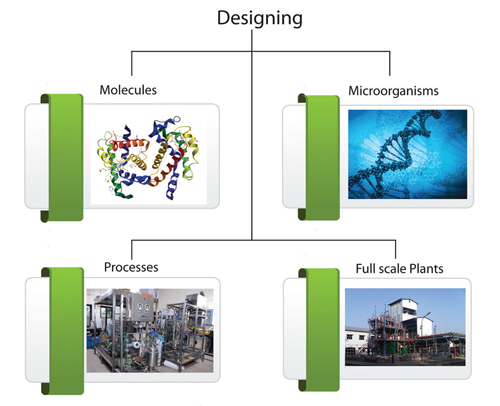

Comprised today of six working groups, the centre focuses on creating a vibrant bioscience and bioengineering platform for developing and demonstrating viable technologies for bio-alcohols, bio-based products and other advanced biofuels production. In addition to the Biofuel program, the Centre also focuses on providing solutions in the areas of Bio-purifications and Bio-transformations for pharmaceuticals, food and other applied sectors of biotechnology.

CAPABILITIES

AIMS

Envisage the end goals as clearly as possible at all times Put all multiple disciplines to work in close co-ordination Combine expertise at two ends of the spectrum i.e. molecular biology and engineering sciences Scale up and apply evolving principles/ideas progressively alongside development in order to make sure that efforts are time efficient and not wasted and the technology zeroes to viability at a faster rate

BIOFUELS TECHNOLOGY

Objectives

- Developing second and next generation sustainable biofuel technologies

- Development of biorefinery concept through multiproduct processing

- Scaling up and implementing biofuel plants in decentralized manner

Approaches

- Innovative pre-treatment strategies

- Radical intensification for enzyme process

- Intensification of fermentation steps

Achievements

- Technology developed for pretreatment of low & high lignin biomass

- Production of separate enzyme amenable cellulose and hemicellulose fractions along with lignin

- Novel two step continuous enzyme process with rapid reaction rates and reduction in enzyme dosage and reaction time

- More than 90 % yield of sugars from biomass

- High ethanol tolerant strains for C5 & C6 fermentation

- High cell density column fermentors

- More than 90 % theoretical yield

- Low cost Pervaporation& distillation system

Technology Highlights

- Continuous process throughout; low CAPEX & low plant footprint

- Biomass to ethanol in less than 24 hours

- Ethanol yield > 300 L/Ton biomass

- Technology components patent protected worldwide

- IGL Pilot plant operational from April 2012 and first phase commissioned successfully

ENZYME TECHNOLOGY

Objectives

- To develop viable processes for microbial/enzyme catalyzed bio-transformations

- Develop stable immobilized biocatalyst preparations

- Production and cost effective purification of expressed biocatalyst

- Bioreactor designs for process scale-up

- Engineer/develop specific enzymes with desired activity profiles

- Develop suitable over-expression systems for selected biocatalysts

Approaches

- In silico biocatalyst structurefunction relationship studies

- Reaction/ Biocatalyst engineering

- Integration of processes

- Process scale up

- Reactor engineering

FERMENTATION TECHNOLOGY

Objectives

- Identifying and designing microorganisms, for biofuel

- Lab scale optimization and production

- to develope technology and process for large scale economic fermentation production

Approaches

- Modification of growth phases

- Media engineering

- Fermentor design

- Extractive fermentation

- Metabolomics & metabolic flux modeling

ALGAL BIOTECHNOLOGY

Objectives

- Explore algae as a source of biofuel feedstock/biodiesel/ value added products

- Develop knowledge, technology and process strategies for sustainable production of algae as feedstock for fuel & chemicals

- Photo bioreactor/Raceway pond designing for efficient scale up of algae as biofuel feedstock

Approaches

- Screening & selection of algae

- Growth and media engineering, consortia design, CO2 mitigation

- Strain improvement by genetic modification/meta bolic engineering/hybridization

- Photo bioreactor/Raceway pond designing

- Harvesting and processing

SYNTHETIC BIOLOGY

Objectives

- Synthesis of drop in biofuels (butanol, biodiesel, biohydrocarbons)

- Large scale bioproduction of amino acids

- Synthesis of furanics from biomass

Approaches

- Pathway analysis for redirecting fluxes towards biofuel production

- Construction of synthetic metabolic pathways for production of high value compounds

- Vector construction for shuttle/ transient/integrative cloning and expression of genes

- Recombinational methods for over expression /silencing of genes

- Alleviating product toxicity in biofuel production by directed evolution for tolerant strains

BIOPROCESS TECHNOLOGY

Objectives

- Thermodynamic & hydrodynamic characterization of various adsorbents for RPC, NPC, HIC, HCIC, IEX, Affinity, IMAC, SEC & mixed mode chromatography

- Design & development of separations of bio-based, natural, synthetic & semi synthetic

products using adsorptive& chromatographic separation

- To improve the product purity, productivity and process economics (commercial viability) through designing of selectivity and process engineering

- Designing of membrane (UF, MF and NF) and extractive separation, crystallization and precipitation (use of smart polymers and poly/ electrolytes) and to explore their possible integration with chromatographic separation

- Mechanistic and empirical models for adsorption and separation mechanisms

- Process monitoring through process optimization and product characterization

- Designing, engineering and scale up of chromatographic reactors (Packed bed, EBA, FBA, SMB, FMB, Segmented), skids as well as pilot and production plants

Approaches

- High Throughput Process Development (HTPD)

- Selectivity Engineering

- Process Integration and intensification

- Quality by Design (QbD)

- Reactor design and engineering

- PAT (Process Analytical Technology) and controls

- Design of adsorbents and affinity ligands

- Process and product characterization, Validation and risk analysis

- Computational fluid dynamics

IP MANAGEMENT TECHNOLOGY AND COMMERCIALIZATION UNIT

Objectives

- Capacity building within the centre in IP Management

- IP protection to technologies generated at the centre

- IP Management with regards to technology transfer and licensing

Approaches

- Filing of Indian, PCT’s, and foreign patents

- Spreading awareness on IP issues

- Preparing MOUs, CDAs/ NDAs and MTAs